Counterfeiting (Duplication) is a significant issue worldwide, affecting products ranging from luxury items to essential medicines. This not only causes financial losses but also poses serious health risks. To tackle this, scientists have developed a new and clever way to stop counterfeiters, inspired by the unique patterns found in the human eye. This new method, developed by a team of researchers from South Korea, promises to make creating fake products much harder for people.

Cheolheon Park, one of the leading scientists, explained, “We wanted to make a security feature so unique and detailed that it would be almost impossible to copy.” They turned to the human iris for inspiration, which has unique and complex patterns. Using these patterns, they created tiny particles that act like security tags. These small particles are perfect for checking if liquid products like medicines and cosmetics are real or fake.

The way they make these iris-inspired particles is exciting and quite detailed. It starts with a process called photolithography, which uses light to create very detailed patterns on the particles. By controlling the light carefully, they can make different shapes and sizes. Minhyuk Lee, another scientist on the team, said, “We used this light process to get very detailed and programmable designs.”

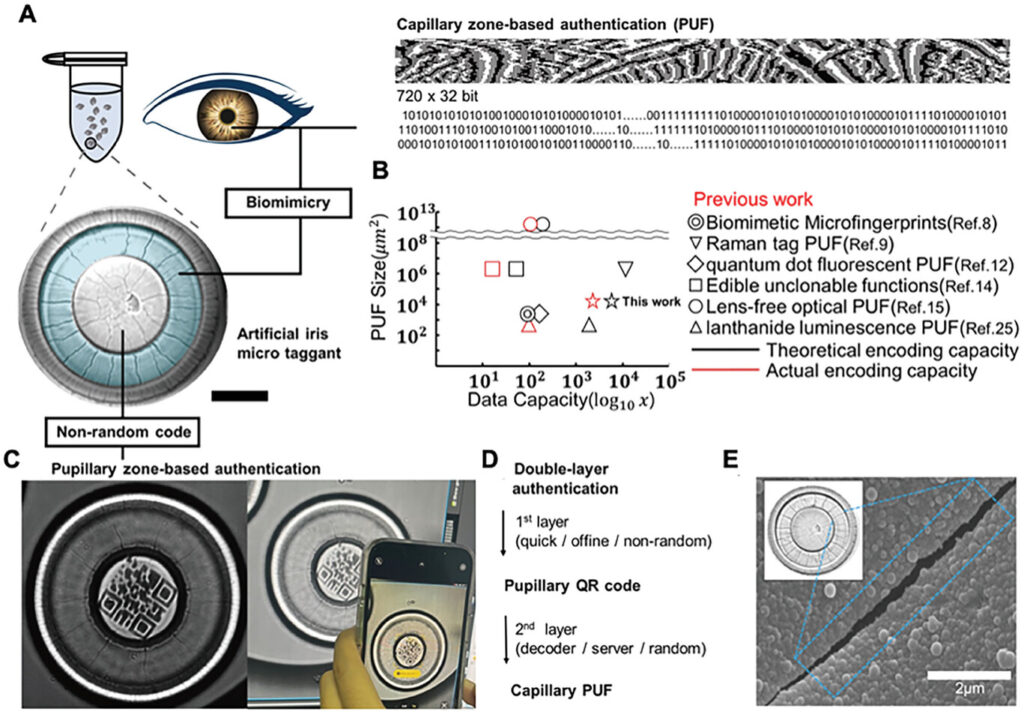

Image courtesy of Advanced Materials Technologies. This illustration A) Shows a comparison between the artificial iris-mimicking microparticle and a real iris, along with the binary code used in iris recognition algorithms. B) Compares the data capacity of different Physical Unclonable Functions (PUFs) from various studies with the artificial iris-mimicking microparticles. C) Displays images of a particle featuring a QR code and another image showing the QR code being scanned. D) Illustrates the two-factor authentication process. E) An SEM image highlights the cracks in the artificial iris-mimicking microparticle (scale bar: 2 µm).

Next, these particles are coated with a thin layer of silica, which is a rigid material. This layer develops random cracks that look like the patterns in a human iris. The final step is to put these particles through a process that makes them swell and shrink, causing the cracks to form. This ensures that each tiny particle is unique. “The randomness of the cracks is essential for creating an unreplicable security feature,” added Wook Park, another scientist on the team.

One of the most excellent parts of this technology is its two security layers. Each tiny particle not only has unique iris-like patterns but also includes a QR code. This QR code can be scanned for a first check, providing basic information about the product. The second check comes from the unique crack patterns in the silica layer. These features make it very hard for counterfeiters to create fake products. As Park highlighted, “This dual authentication system ensures that even if one layer is compromised, the other remains a strong line of defence.”

The potential uses of this technology are enormous. In the medicine industry, these tiny particles can help ensure that liquid medicines are genuine and safe to use. The cosmetics industry can also use them to protect high-value products from being faked. This technology can also be applied to any liquid product, making it useful in many fields. The ability to work in wet environments significantly improves over older methods, which often don’t work well with liquids.

The process of making these particles is quite detailed. First, they create the basic shape of the particles using light. This step allows them to make different parts of the particle with various heights and strengths. The capillary zone, which will get the cracks, is made to be very elastic, while the other parts are made more robust. This difference is essential for the next steps.

After creating the basic shape, they coat the particles with a thin layer of silica. This hard layer will develop cracks that are unique to each particle. To create the cracks, they use a process that makes the particles swell with water and then dry out. This swelling and drying cause the silica layer to crack in random patterns. These cracks make each particle unique, just like the patterns in a human iris.

The scientists meticulously control the formation of the cracks in the silica layer. They employ the Flory–Rehner theory to understand the swelling and shrinking behavior of the particles. By adjusting the exposure time to UV light, they can control the crosslinking density of the polymer, which in turn influences the pattern of the cracks. This meticulous control is crucial in ensuring that each particle has a unique pattern, enhancing the reliability of the technology.

“Our commitment to ensuring the reliability of this technology led us to conduct rigorous testing. We tested the particles to ensure they could be used in real-world applications, and we found that they performed well even in wet conditions, a critical factor for products like medicines and cosmetics. We also tested how well the particles could be authenticated. We used a process similar to iris recognition, where we took an image of the particle, extracted the features from the cracks, and compared them to a database. This process demonstrated that the particles could be uniquely identified, making them highly effective for preventing counterfeiting.” Minhyuk Lee stated.

One of the key advantages of this technology is its ability to provide two-factor authentication. The first factor is the QR code, which can be scanned to provide basic information about the product. This is useful for quick checks and can be done without a connection to a database. The second factor is the unique crack pattern, which provides a much higher level of security. This pattern can be checked against a database to ensure the product is genuine. This dual-layer security makes it very difficult for counterfeiters to create fake products that can pass both checks.

The versatility of this technology is evident in its potential applications. In the pharmaceutical industry, it can ensure the safety and authenticity of medicines, protecting patients from harmful counterfeit drugs. In the cosmetics industry, it can safeguard brands from revenue loss due to counterfeit products and ensure that consumers receive the quality they expect. Its applicability extends to other sectors where liquid products are prevalent, offering a versatile solution for a wide range of applications.

In conclusion, the development of these iris-inspired microparticles is a significant step forward in the fight against counterfeiting. By mimicking the unique patterns of the human iris and incorporating a QR code for dual authentication, this technology offers a robust solution for a wide range of products. As Park succinctly put it, “This technology not only enhances the integrity and safety of goods but also helps to restore trust in markets and institutions affected by counterfeiting.” This innovative approach holds great promise for creating a more secure and reliable future for both consumers and businesses.

C. Park, M. Lee, H. Kim, D. Lee, J. Choi, Y. Choi, W. Park, Iris-Inspired Microparticles with a Two-Factor Authentication Security Feature for Wet-Phase Enhanced Anti-Counterfeiting Strategies. Adv. Mater. Technol. 2024, 2400566. https://doi.org/10.1002/admt.202400566